USETI SDS, HeroX- Technical Narrative - June 2020

USETI Solar

Desalination

System

USE Thermo Innovations Inc.

2722 Cityland Shaw Tower, Shaw Blvd cor. St. Francis St,

Wack-Wack Greenhills East Mandaluyong City 1552 Philippines

Phone: +63 927 483 9644

1 Technical Narrative

Today, desalination plants worldwide produces bigger-than- expected flows of highly salty wastewater and toxic chemicals damaging the environment. The hyper-salty water is mostly pumped into the sea and, over a year, would be enough to cover the U.S. state of Florida with 30 cm (one foot) of brine.

The desalination plants use large amount of electrical energy to filter the seawater making drinkable water and thereby depending on a large power supply. Therefore, it is obvious to use solar thermal energy to drive the desalination process and thereby make the system as Green Clean Technology and minimizing / removing the electrical consumption to make desalination.

The solar thermal powered USETI SDS solution will save more than 90% of the electricity consumption compared to conventional desalination systems and can further be made as a self-standing unit all driven by the sun.

The USETI SDS (USETI Solar Desalination System) solution is a revolutionary novelty in the field of desalination which is expected to gain a significant market share due to its cost effectiveness, and its positive impact on the environment thanks to the reduced CO2- emissions.

USETI's mission as a company is to develop a thermo desalination solution driven by solar heat panels. USETI is seeking partnership with one or more (industrial) investors for the production, marketing and distribution of the USETI SDS.

USETI now faces the challenge of initiating a commercial exploitation of this technology in order to take full advantage of this growing market.

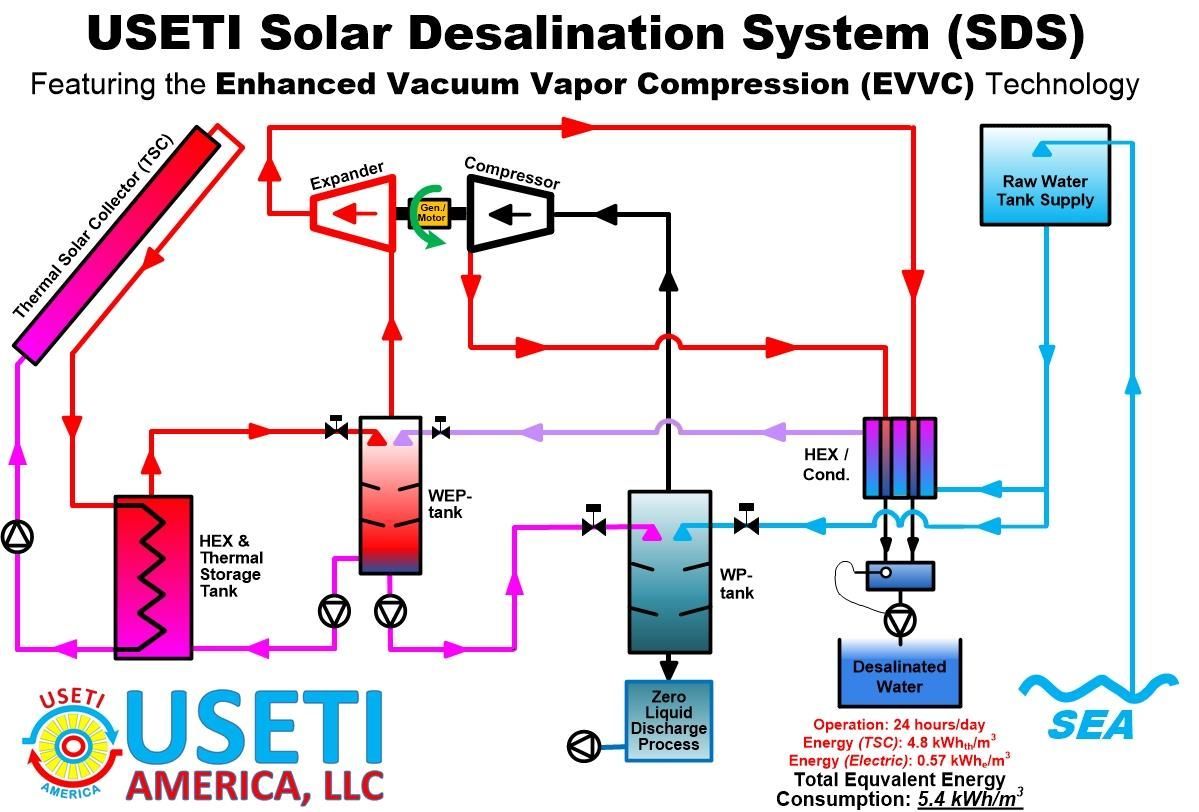

The USETI Team has developed a turbo expander making the flow of pure drinking water as a process medium under low pressure and temperatures. The expander drives a compressor that combined makes the flow of pure drinking water in the desalination process.

The success criterion is to exploit a series of thermo processes well-known as such & which never have been combined into one functioning desalting unit so far.

The company will take the new desalination process to Proof Of Concept. The desalination process uses the same turbine setup innovated by USETI and installed on an air condition system where Proof Of Concept already has been achieved.

The brackish- / seawater creates a vapour flow when it boils (vacuum) which is removed and expanded / compressed in the turbine, thereby heating the vapour to temperatures of between 125°C to 175°C. This causes the resulting pure vapour flow to be sterilized (bacterially-/virus free) before condensing to absolutely pure drinking water.

2 Company Profile

2.1 Idea Concept

The basic idea is to develop and design a desalination system powered by solar thermal energy, producing hot sterilized pure clean drinkable water derived from brackish- or seawater. Thanks to a low production cost, enormous savings in power consumption and therefore great environmental considerations, the concept is unique compared to conventional desalination / desalting systems.

2.2 Patent

The USETI process is patented. The patent deals with the process and component setup.

2.3 Company Profile

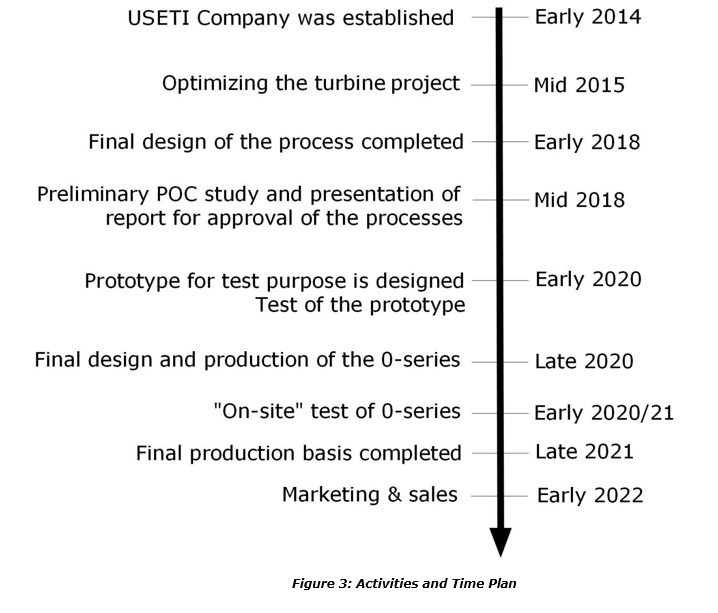

The company USETI was established early 2014 with the purpose of developing a revolutionary new generation of AC systems together with desalination systems where 95% of the energy is generated by solar thermal collectors while the remaining 5% by solar photovoltaic cells or other sources.

The company is a design and development company with a proven track record in thermodynamics and with the skills and know-how to develop and test the concept of the thermal driven plant.

The company offers the following services in that we can:

· Design and process the development of the concept

· Test and promote the results

· Provide information and media coverage of the process

· Take care of direct sales of licenses, production rights, and know-how

· Organize sales promotional activities in the form of articles to the technical press and participate in trade shows and the technical communities

· Manage the development process

· Maintain the patents and trademarks

2.4 Mission Statement

The mission of USETI is to develop and commercialize a thermal- driven desalination solution driven by conventional solar thermal collectors and/or waste heat.

3 Historical Review

3.1 Vacuum Boiling

The history of using vacuum boiling water in large plants started back in the 1990´ at DTI (Danish Technological Institute). A turbine compressor removes vapour steam in the evaporator and cools thereby another media.

3.2 Cooling LEGO

The cooling system with water as a refrigerant, was developed and created in collaboration between the DTI in Aarhus (by Gunnar Minds, then employed at DTI), LEGO and Sabroe, where the DTI had the design responsibility.

The plant had a cooling capacity of approx. 2 MW and was started in mid-1995. The plant's cooling performance was used to cool LEGO's plastic sewing machines. The design of the plant contained a great deal of new thinking, which has been and later will be explained in other sections.

The plant was honoured by the Danish Engineering Association and EU Environment Agency in 1996.

water as a refrigerant

The first actual functioning plant at LEGO in Denmark shown above in the picture had a diameter on around 3.5 m & a length on around 7 m giving a volume flow of steam on approx. 200 m3 / sec.

New plant developed at Danish Technological Institute to the right in the picture designed 1998 – 2005 with a volume flow of steam on approx. 25 m3 / sec.

Marketed today e.g. by Johnson Control, Denmark (formerly Sabroe A/S). A new cooling plant is today located at LEGO in Billund, Denmark and has replaced the first plant that has been stopped (after 15 years activity).

3.3 USETI

Gunnar Minds and Søren Minds from Denmark have together with Jose Jobel Belarmino, Ramil Sevilla and Reggie Ramirez from Philippines developed USETI.

USETI has carried out a number of experiments with a solution using a Boot Strapped refrigeration system where an expander drives a compressor on the same shaft (a little turbo compressor).

The expander and compressor use water as the driving and coolant media respectively. The energy supply to the process comes from solar collectors or waste heat water at temperatures below 100°C, preferable 75°C, and thereby useful as a stand-alone unit.

The principle using a cooling setup is the same as in USETI SDS desalination process, where the “evaporation” also can be the separation process between water and all other stuff (salt + others). Both the separation- and traditional evaporation setup are durable processes and use the same turbine construction.

3.4 Commercial Opportunity

Today, desalination plants worldwide use tremendous amount of electricity and produce bigger-than-expected flows of highly salty wastewater and toxic chemicals damaging the environment.

To address the high cost of electricity, we use solar as the source of energy to run the desalination system. Up to 95% solar thermal and 5% solar PV or other sources.

3.5 Technical Description of the System

The USETI SDS is based on well-known thermal processes:

- A conventional solar thermal collector produces low temperature steam on the incoming brackish or seawater

- The steam & salt separator divides the steam to flow into the steam turbine.

- In the expander (turbine) the energy of the steam is converted into rotational energy which drives a compressor on the same shaft. The expander & compressor delivers sterilizes pure clean water in the desalination process

- The steam produced in the desalination process is finally condensed in an air-cooled condenser. The sterilized water will go through a remineralization process before becoming available as safe and healthy drinkable water.

The distillation process happens when the water is converted into steam by boiling. The boiling process makes almost completely pure water (99.9%). The steam is subsequently heated up in the turbine to above 125°C. This process sterilizes the water steam making the condensed water totally clean and potable. Final stage of the process is to remineralize the clean water with small amount of calcium carbonate, fluoride and magnesium & follows #1, #2 & #3.

The desalination plant is a closed self-contained unit, and only needs to be connected to the solar thermal collector.

The separation evaporation process shown in Figure 2 only produces pure potable water, whereas the traditional evaporation setup produces pure drinking water and crystallized salt.

4.3 Technical Performance

USETI SDS unit, design basis:

The design capacity is based on following.

Solar Collector Temperature 75˚C (range 60 – 80˚C) Desalination Capacity 200 liter drinkable water / day Solar Collector Capacity 10 kW (10 m2, Equator)

Power Consumption 0 W

The desalination capacity can be increased by spraying water in the condenser airflow.

4.4 Proof of Concept, POC

USETI has made a preliminary POC investigation into the technical and thermodynamic challenges in collaboration with one of the world's leading companies in thermodynamics - #4. Report confirms the theories with the following conclusions.

The POC confirms the following parameters:

· A cycle has been identified that will allow for optimal operation of both the compressor and expander

· Structural design confirms that tip speed on expander / compressor are within the range of past experience

· Rotor dynamics are acceptable

· No manufacturing problems are foreseen

4.5 Activities and Time Plan

4.6 Critical Technical Components

The turbine, making flow in the desalination process, has been through several test hours to reach the optimal solution.

This is the critical component in the construction and made up a large part of the development work, of which the following are mentioned: shaft bearing solutions, leaks, lubrication, cavitation & high temperatures. The turbine now functions as a thoroughly tested unit.

Other main components in the USETI SDS unit are traditional mass produced components, solar collector, condenser, pumps.

5 Competition

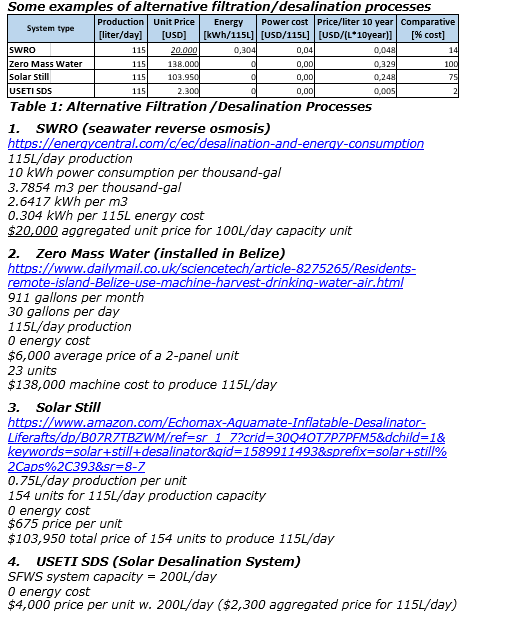

Already well-developed and with a rapid growth rate, the desalination market has a number of large players. Below are some of the competitors which can be divided into two major groups: companies supplying traditional electrical-driven desalination filtration systems and companies supplying systems that capture air humidity to make drinkable water.

Both groups are supplying systems based on conventional technologies. Considering the calculated lower production costs of the units and the annual savings on the energy bill in reference to the water capacity, these make the USETI SDS unit to have a significant competitive advantage.

5.1 Alternative Filtration/Desalination Processes

The electrical-powered desalination process has been known for several decades.

Literature Reference

#1: “Desalination for Safe Water Supply” by WHO/SDE/WSH/07/0? Guidance for the Health and Environmental Aspects Applicable to Desalination w. file name “DesalGuidanceMaster4July2007-1JAC”

#2: “Philippine National Standards for Drinking Water 2007” by Republic of the Philippines, Department of Health, OFFICE OF THE SECRETARY ADMINISTRATIVE ORDER No. 2007- 0012

#3: M. Rygaard, E. Arvin, A. Bath, P.J. Binning, Designing water supplies: Optimizing drinking water composition for maximum economic benefit, Water Research, Volume 45, Issue 12, June 2011, Pages 3712-3722, ISSN 0043-1354

#4: Concepts NREC, VT 05001, USA; World leading company designing i.e. turbocharger, both axial and radial setup and in special designing small steam expanders/compressors

New Paragraph

USETI PILOT CHILLER PLANT

Overall, the vapor compression system represents a promising technology that can benefit a wide range of industries & applications, from cooling and energy production to water desalination and beyond .