A Solution to the Drought Crisis - USETI SDS with EVVC

We are all familiar with the water crisis that is happening. It has been here before in a more dissolved form. Solved by a few rainy years, the crisis goes away. These few years of inclement weather might be Mother Nature’s way of telling us the drought is long overdue.

Reduction in household water use - that will not work! Water for drinking and other domestic water uses are undoubtedly important due to the direct impact on our everyday lives. It may have the major audience in this crisis, but looking at the bigger picture of the water problem, it is a smaller issue. Equal if not more focus and efforts must likewise be exerted on the big water takers - the industrial and agricultural sector.

These sectors have the biggest impact on us (people) because their water use provides the convenience of food that we all consume as well as services that we use daily. They are the prime consumers of water. We, the people, only have a small influence but with the largest voice in this crisis.

(How We Use Water | WaterSense | US EPA)

The USETI Group are middle aged innovators who care about the future of our next generations. We may not ever see the impact of our innovations, if ever in use. But what is important is that the future generation be able to reach farther in their lives and in success than we did, with a climate that is comfortable for all, and water resources available when needed.

So, we decided to tackle the nexus of Water, Climate and Energy using water as the medium.

With water, we bring to the world a simple yet very efficient USETI Solar Desalination System (SDS). In the climate area, we have the USETI Solar Air-conditioner (SA). Both these products use the same core technology. In the near future, in the energy space, we want to solve the challenges of hydrogen energy generation, using of course, water and discovering its large mysterious uncharted properties. We are almost there.

Søren Minds Ramil Sevilla

Founder, Innovator, CTO, Denmark Co-founder, CEO, Philippines

Jojo Pornebo Loreto Bagio

Co-founder, MD, USA (CA) Co-founder, COO, USA (CA)

Novel

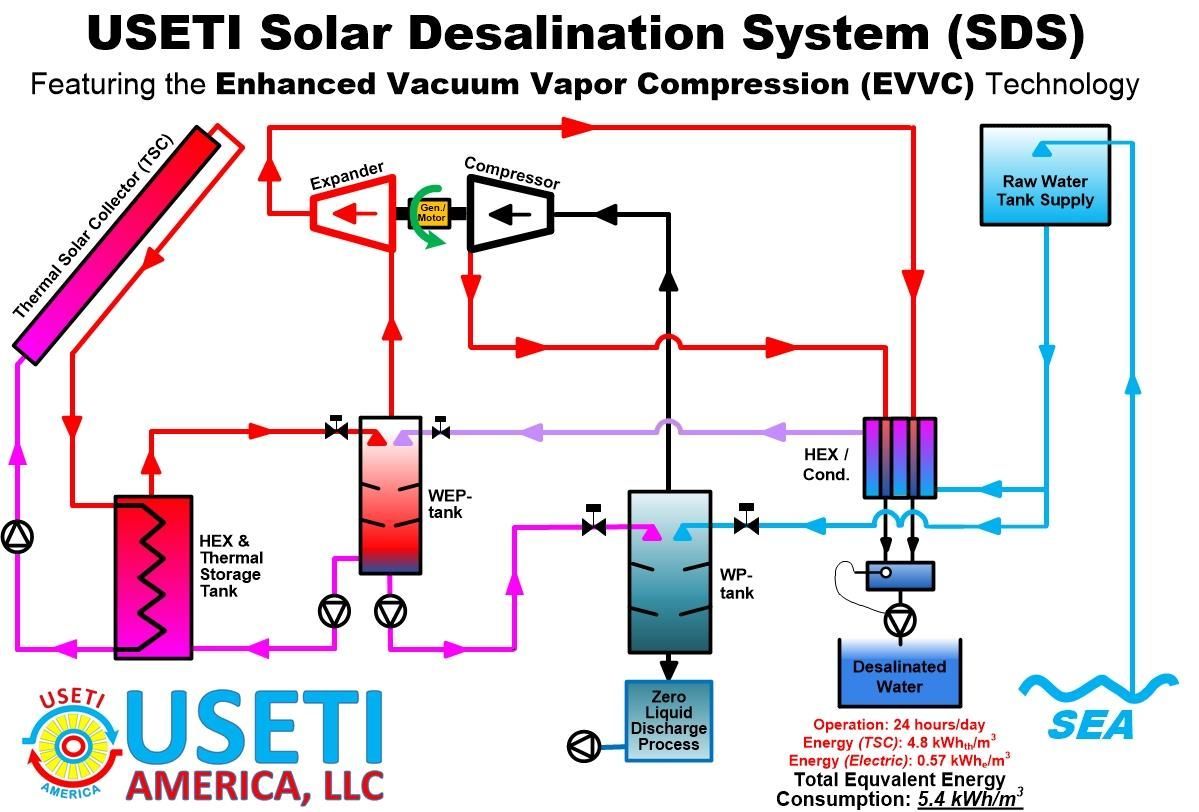

USETI SDS (Solar Desalination System) is an Enhanced Vacuum Vapor Compression (EVVC) thermal desalination system that produces desalinated water through the use of a turbine-expander-compressor.

EVVC is a form of Mechanical Vapor Compression (MVC) desalination, but unlike typical MVC desalination which uses extensive electrical energy. The USETI SDS EVVC uses a combination turbine-expander-compressor mounted on the same shaft powered by thermal energy.

Using a turbine compressor as the compression device driven by a turbine expander solves the MVC desalination-energy cost issue. In addition, just like an MVC, USETI SDS is assumed to have a

smaller footprint than MED or MSF desalination systems.

USETI SDS uses a turbine expander constantly powered by a thermal storage which collects thermal solar energy from a thermal solar collector. The USETI SDS is not directly affected by the intermittent thermal solar radiation on a 24-hour per day operation. It can also be re-designed to collect any kind

of available heat source, or even total electrical driven (high COPe) / producing electricity.

In the EVVC, the turbine-compressor rapidly processes steam produced from the boiling water. Additionally, the turbine-compressor is driven by a turbine-expander mounted on the same shaft. The turbine-expander can also produce about the same amount of desalinated water as the turbine-compressor at the same time increasing the total water production.

The EVVC technology is a single stage vacuum compression system producing water simultaneously from both outlets of the turbine-compressor and the turbine-expander. Sensible heat from the compressor outlet is used as additional heat in the system for increased water production. In this single stage system design, excess heat is recovered and used to pre-heat the incoming flow of raw water. In comparison, MFD and MED use multi stage distillation to produce water - the design of these systems is complex and can have multiple failure points.

USETI SDS EVVC technology operates below atmospheric pressure across the core desalination system. This low-pressure environment reduces operational risks. The maximum pressure that can be present in the system is below 2 bar,a pressure (bar absolute).

The USETI SDS turbine compressor wheel tip is specially designed with a velocity of Mach 1.4 to achieve a very high target compression rate of 1:4 producing 2.5 times as much pressure flow than a normal turbine wheel tip speed. These results in smaller processing tanks, pipes, valves, heat exchangers / condensers and pumps because of the high steam flow rate of the turbine compressor.

The turbine compressor produces superheated steam at a high temperature used as a feedback heat recovery to the turbine cycle further increasing the performance of the turbine operation.

Costs

● Equipment cost

The simple single stage design benefits from the dramatic reduction of capital costs. The fast steam flow processing due to the high turbine rotation requires small system component sizes, which includes the turbine-expander-compressor, processing tanks, pipes, pumps, heat exchangers and condensers.

All raw materials used in the USETI SDS components are widely available including the materials to manufacture the turbine-expander-compressor, contributing to low equipment construction costs.

Operational cost

Energy: The USETI SDS design use the free and inexhaustible thermal solar energy. Majority of its energy requirement (around 88%) is thermal energy. Minor electrical energy requirements are for operating the pumps, valves, and controls but are significantly low. In addition, operational cost is reduced with increased production efficiency from the use of a turbine-expander-compressor. Sensible heat from the turbine compressor outlet is recovered for heat energy input to the turbine expander. Furthermore, after driving the turbine expander the used output steam is converted to desalinated water.

Only 4.8 kWh of thermal energy is required to produce 1 cubic meter of desalinated water. Also, only 0.57 kWh of electrical energy is required. The USETI SDS’ Total Equivalent Energy Consumption is 5.4 kWh/m3 giving a Total Equivalent Electrical Energy on 1.2 kWh/m3.

Maintenance: With a single stage design, and especially with the use of smaller turbines, tanks

and components, the USETI SDS is a low maintenance system. There will be fewer components requiring periodic checks, much less repair. The boiling temp is set at 70°C to prevent scaling in the metal components.

Points of Failure: USETI SDS has a simple single stage design. The only primary moving part is the turbine. However, well-designed steam turbines typically last around 20 years and should be repairable.

Conclusion

USETI SDS EVVC offers significant advancements over all current and popular thermal desalination technologies in terms of operational costs (thermal energy consumption), performance (rate of water production), and capital costs (materials & system area footprint).

Thermal Storage Component

To make effective use of a 24-hour operation without dependency on the intermittent solar radiation; it will require constant supply of thermal energy. A high capacity thermal storage can be built (based on a published article - https://doi.org/10.1080/23311916.2018.1538490) using concrete and graphite as the heat capacity hybrid materials increasing the combined heat capacity to 1.6 times compared to cement and aggregate alone. In addition, graphite has a high thermal coefficient which means it will easily conduct heat to charge the thermal battery, reducing the thermal storage charging time. Lastly, this novel

thermal storage idea has a slow discharging rate which is needed for the low thermal energy requirement of the USETI SDS in a 24-hour operation.

Scalability and Applications

The USETI SDS desalination design is scalable to small capacities as low as 0.2 m3 per day, to even millions of gallons of desalinated water per day. This scalability caters to a wide variety of target markets - consumer, commercial and industrial applications. The niche markets are marine applications, remote small coastal and island communities, agricultural applications, mining operations, and self-supplied domestic applications, etc. In the following USETI SDS will produce 100 m3 desalinated water per day.

Technically Feasible

Complete System Operation

Figure 1: Flow Diagram of the USETI SDS Core Operation and an Electic generator/-Motor Option

To produce 100 m3 per day of desalinated water, the USETI SDS process starts with “raw water” stored in the seawater/brackish water supply tank flowing into a “Water and Energy Production” evaporation tank (WEP-tank). The WEP-tank is supplied with raw water heated by the Thermal Storage Tank at a temperature of 70°C to prevent scaling, at a flow rate of 75 m3/hour. The WEP-tank pressure is reduced to 0.25 bar,a to boil the water and produce steam at the top section of the WEP-tank.

The steam flows to the turbo expander inlet at a flow rate of 2.6 m3/s with high enough

temperature to rotate the expander wheel at 45,000 RPM. The steam pressure and temp.

at the turbine expander outlet is decreased at a flow rate of 16.2 m3/s. The output steam passes

through a condenser / heat exchanger (HEX/Cond.) converting the steam into desalinated water. The

turbine expander is generating desalinated water, and at the same time, supplying rotational energy to

the turbine compressor. This innovative process contributes significantly to the water production without the need for additional components, in addition to the water production in the compression cycle explained later. The WEP-Expander cycle produces water at the rate of 45 m3/day in a continuous 24-hour operation.

The latent and sensible heat from the condenser (during the WEP-Expander cycle) increases the

temperature of the brine in the WEP-tank. The brine in the WEP-tank is fed into the “Water-Production”

(WP) tank to start the WP-Compression cycle. The pressure in the WP-tank is reduced to minimal 0.06

bar,a to boil the water and produce steam. The steam flows into the turbine compressor inlet at a flow rate

of maximal 16 m3/s, at min 35°C. The turbine compressor is already spinning at the same rotational speed

as the turbine expander wheel (during the WEP-Expander cycle) because both wheels are connected to

the same shaft. The steam directed to the turbine compressor is with a flow rate of minimal 4 m3/s. After

which, the steam from the heat exchanger outlet flows through a HEX/Cond. at a flow rate of 3.5 m3/s

converting the steam into desalinated water. The WP-Compressor cycle produces water at the rate

of 55 m3/day in a continuous 24-hour operation.

Excess heat from both the WEP-Expander and WP-Compressor cycle is recovered for re-use. The

HEX/Cond. recovers the latent heat then fed back to the WEP-tank increasing the temperature in the

tank.

The USETI SDS produces desalinated water from the combined WEP-Expander cycle and the WP-Compressor cycle. EVVC is made feasible with the use of a turbine-expander-compressor operating in

tandem, as opposed to a conventional compressor (like MVC) driven by electricity. EVVC can desalinate

raw water with a reduced system core form factor size. Its thermal energy requirement to produce 1

cubic meter of water is 4.8 kWhth. An additional 0.57 kWhe of electrical power per cubic meter of water

is consumed for operating the electrical pumps and other electrical devices. The total water production

from both the WEP-Expander and WP-Compressor cycle is around 100 m3 per day.

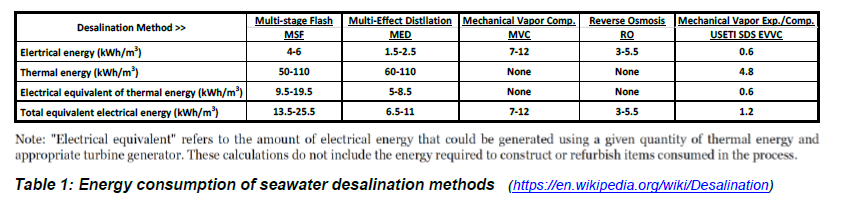

Comparing to other desalination plants, USETI SDS has a significant lower use of both electrical and

thermal energy, which, in the value of Total Equivalent Electrical Energy, equals 1.2 kWh/m3. Table 1

below has been added USETI SDS EVVC as a basis for comparison of existing desalination methods.

USETI SDS cost to desalinate water in USA

The unit cost of Desalinated Seawater (D.S) is affected by several factors, including capital expenses, debt service, and operating costs. According to Google, the current unit cost of D.S ranges between US$ 3.6 & US$ 5.8 per 1,000 gallons, depending on the region and other factors such as energy costs and plant size.

Unit cost by USETI SDS EVVC

1,000 gallons = 3.785 m³

1 m³ desalinated seawater (D.S) cost today: US$ 3.6 / 3.785 m³ = US$ 0.95 / m³

(Google, 2023) US$ 5.8 / 3.785 m³ = US$ 1.53 / m³

Electrical cost in USA: US$ 0.135 / kWh (business price in USA)

Electrical cost of D.S by USETI SDS EVVC: 0.57 kWhe / m³ · US$ 0.135 / kWh = US$ 0.077 / m³

The USETI SDS EVVC technology makes it possible to desalinate seawater for less than US$ 0.10 per m³. This low unit cost includes operating expenses, but not investment capital & debt service. During a 10-year investment period, the estimated fixed expenses will increase the unit cost per m³ D.S by less than 50%.

Unit Cost of D.S by USETI SDS EVVC: US$ 0.077 / m³ + 50% ≈ US$ 0.12 per m³ D.S

(≈ US$ 0.45 per 1,000 gallons ➔ 10% of today’s middle unit cost of D.S, year 2023)

Zero Liquid Discharge (ZLD) Operation

The EVVC, since it is a single turbine stage desalination design, is continually removing the water content from the WEP-tank in a repeating cycle producing hypersaline brine at the bottom of the WEP-tank. The hypersaline brine is fed to the WP-tank for further removal of water content. The WP-tank can receive raw water input (option). Both flows make it possible to produce hypersaline brine (slurry) from this tank. When the WP-tank is nearly full of (slurry) hypersaline brine then its contents are discharged to a brine tank for further ZLD processing. The hypersaline brine (slurry) is removed and pressurized by a sludge pump for further use at atmospheric pressure. The external ZLD process can include final evaporation of the water content using less energy expensive evaporative systems, such as waste heat transfer.

Dealing with toxic PFAS

Known colloquially as “forever chemicals”. PFAS, short for per- and polyfluoroalkyl substances, are a large group of chemicals that make certain products nonstick or stain resistant. Research indicates that these chemicals are dangerous.

The USETI SDS EVVC uses vacuum to desalinate seawater, and this process produces hypersaline water (brine) that is discharged into the bottom of the WP-tank. This discharged hypersaline water may also contain any conceivable PFAS or other harmful substances that were in the seawater.

The cleaning effect against PFAS using vacuum is announced in a recently published article – https://www.yasa.ltd/post/how-to-remove-forever-chemicals-pfas-from-water-and-wastewater.

Using USETI SDS EVVC to desalinate seawater (or wastewater) to make drinkable water

thus, also includes a solution to get rid of toxic PFAS and/or other harmful substances.

Thermal Storage Process Operation

The thermal storage is fed with raw water from the WEP-tank to supply the USETI SDS with constant

thermal energy throughout the 24-hour operation. Recirculated brine from the WEP-tank is fed back

to the thermal storage for reheating back to 70°C. The thermal storage is sized bigger than the

daily continuous operational consumption of the USETI SDS to consider solar radiation fluctuations.

The thermal storage is recharged by a solar collector while the thermal storage is in use by the

EVVC.

Thermal Solar Collector (TSC) Component

Thermal solar energy is the primary source for driving the USETI SDS turbines. Any type of highly efficient thermal solar collector system is applicable for use as the charging component for the thermal storage working independently with no physical contact to the EVVC-process only delivering thermal energy means being able to work with another medium ex. clean water, oil, or other TSC-medias.

The solar collector is sized to fully recharge the thermal storage daily, while the thermal storage is simultaneously in use for supplying heat to the USETI SDS, taking into consideration sizing the solar collection for lean solar radiation months using official solar radiation data from NREL (USA). Right-sizing the thermal solar capacity can overcome unpredictable solar radiation fluctuations

that may impact the charging cycle of the thermal storage.

Thermal solar energy is fed through an embedded heat exchanger in the thermal storage. Using

an efficient heat transfer mechanism to charge the thermal storage will take advantage of the

fast charging capability of the thermal storage.

Required milestones

- Turbine-expander-compressor redesign

The USETI turbine-expander-compressor with heat recovery core technology has been functionally proven for an air-conditioning application in a prototyping environment. For water desalination application the turbine has to be re-designed for its appropriate scale (100 m3 per day) and be optimized to rotate at approx. 45,000 RPM to achieve a wheel tip speed of Mach 1.4 and a high compressor output pressure.

- Zero Liquid Discharge automation

To attain ZLD, the salt (solutes) must be in crystallized form. The USETI SDS produces hypersaline

brine as a slurry liquid in the WP-tank. However, the correct discharge timing of this slurry brine has to

be calibrated for when the WP-tank is full. The slurry brine can be discharged to a ZLD-tank for complete crystallization. System automation is required to optimize the cycling of the discharge process.

- Thermal Storage and Solar Collector sizing

A thermal storage with the appropriate size has to be built to; continuously supply thermal energy to the USETI SDS for 24 hours; and, simultaneously receive thermal solar charge to the USETI SDS for next day operation.

It is the full intention of USETI America, LLC to move forward in the prototyping of the USETI.

SDS Enhanced Vacuum Vapor Compression concept, and to deliver the USETI SDS to the

commercial and industrial market. The worldwide issue of water shortage is present. Although

the more popular Reverse Osmosis can already provide the water needed, it has a carbon emissions issue with its extensive use of electrical energy, high maintenance of the membranes, and high salinity discharge, while USETI SDS eliminates all of these drawbacks. USETI intends to cooperate with well-established and reputable partners in the relevant areas of the prototype development, focusing on respective core competencies, reducing risks, and expediting the development cycle.

Impactful

EVVC can use the thermal energy efficiently compared to the other thermal desalination systems because it uses the thermal heat as the driving energy aside from water production. It also recovers condenser waste heat for re-use. EVVC is a step ahead of state-of-the-art thermal desalination technologies such as MED, MSF and MVC – see table 1.

Only 4.8 kWh of thermal energy per cubic meter is required. For a production facility of 100 cubic meters per day, a real estate of a 40-foot container (rough estimate) is needed excluding the

raw water tank, the desalinated water tank, the ZLD-tank, the thermal storage and the thermal

solar collector area.

It can produce (close to) ZLD as its by-product. It is essentially a built-in brine concentrator. The hypersaline brine may not have to be reintroduced back to the ocean. The ZLD is delivered to external manufacturers requiring slurry brine as ingredients for their operation. Or, ZLD can be evaporated externally outside of the desalination operations. ZLD has a potential to be used for electrical storage (directly extracting electricity from ZLD thermal batteries) for when the reverse electro dialysis technology is mature (https://en.wikipedia.org/wiki/Reversed_electrodialysis).

USETI SDS construction is simpler due to widely available parts reducing capital costs, in addition

to lower costs due to less energy consumption.

The USETI SDS addresses the government compliance standards in terms of environmental issues.

These advantages will facilitate broad market adoption of the EVVC technology.

New Paragraph

USETI PILOT CHILLER PLANT

Overall, the vapor compression system represents a promising technology that can benefit a wide range of industries & applications, from cooling and energy production to water desalination and beyond .